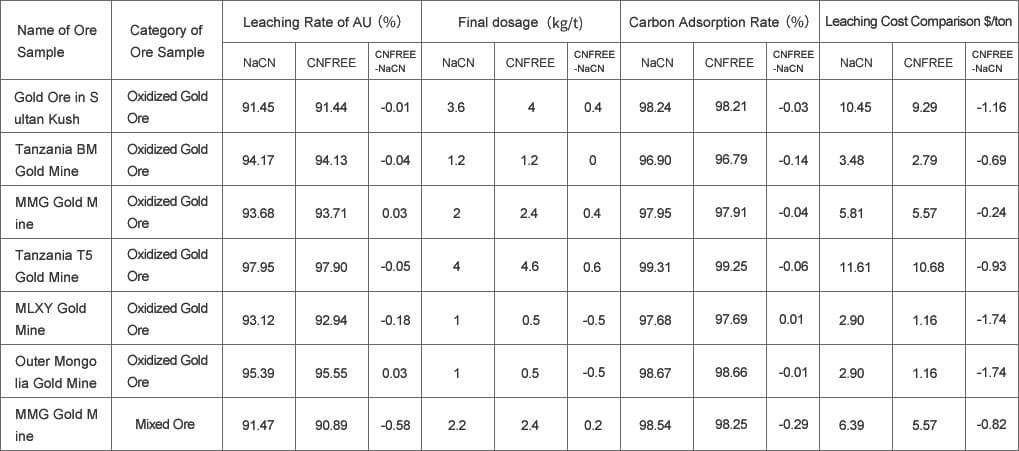

In order to probe the difference of leaching effect between NaCN leaching agent and CNFREE leaching agent on gold ore, ITAO select a total of six gold mineral samples-the Sultan Kush oxidized gold ore, Tanzania(Busolwa Mining Ltd) oxidized gold ore, Tanzania (MMG GOLD LIMITED) oxidized gold ore and mixed ore (containing oxidized ore and primary ore), Tanzania (T5) oxidized gold ore gravity concentration tailings-for leaching comparison test. Under the same cyanide leaching conditions, the differences between NaCN leaching agent and CNFREE leaching agent in leaching agent dosage, leaching rate and gold adsorption rate were emphatically studied, and the economic benefit analysis of the comparable project was also conducted.

Carbon leaching process is characterized by simultaneous gold leaching and adsorption stages, with normal leaching segments of 6-10 segments. In the leaching process, ensure the fineness of grinding products - 200 mesh accounted for 85-95%, the pulp concentration accounts for 40-45%, then add a certain volume of CNFREE ECO gold leaching agent. Make sure the leaching slurry concentration is not less than 0.015% to efficiently leach the gold ore. At the same time, lime is added to maintain a higher pH (10-11).

As the same with conventional cyanidation process, the leaching slurry concentration and the oxygen content in the leaching pulp are strictly controlled during the agitation leaching stage. By adding a certain volume of CNFREE gold environmental leaching agent to adjust the leaching concentration to 0.05% to 0.08%. The oxygen content in the slurry needs to control the aeration volume and the inflation pressure. The general aeration volume is 0.02 m3/m3•min, and the inflation pressure is 100 KPa. It is appropriate to uniformly distribute small bubbles of 5~15mm diameter on the surface of the slurry during production, and control the volume by adjusting the main valve of the air pump and the inflation valve of each tank.

Crushed by jaw crushers and cone crushers to a certain particle size (30-50mm), raw ore is directly sent for heaping or granulated (to make finer particles agglomerate into coarse powder), and then transported to the ore heap site for heap construction. On the laid ore heap site, the heap system is set up. After the reaction of CNFREE gold environmental leaching agent and the ore, thegold-containing solution (pregnant solution) seeps from the bottom of the pulp, flowing into the precious pregnant solution pool, and being pumped into the adsorption column through the pregnant solution pump. The solution after the activated carbon adsorption is lean solution. The lean solution are returned to the spray system for reuse.

The gold mine pool leaching process has strict requirements on the dosage of cyanide solution; too much is of a waste and too little can't guarantee the leaching effect. When using CNFREE eco-friendly gold leaching reagent, the requirements can be appropriately relaxed in terms of dosage,and the same leaching effect of cyanide can be obtained, which saves cost and reduces environmental pollution. Add a small amount of leaching material to the ore, agitate it uniformly and put it into the pool, then spray the leaching solution containing CNFREE gold environmental leaching solution with the spray system to prevent the solidification of gold ore in the pool, and greatly improve the permeability and leaching rate of the gold mine.

In the all sliming zinc powder replacement process, the concentration of CNFREE ECO gold leaching agent and oxygen are closely related to the gold recovery rate. The metal zinc is added to the pregnant solution after purification and deoxidation, after the displacement reaction, the gold in the pregnant solution is replaced by a metal state to precipitate, and the zinc is dissolved in the alkaline leaching slurry. Under the normal zinc powder replacement conditions, the concentration of CNFREE ECO gold leaching agent should be controlled at about 0.02% in the gold-containing solution entering the displacement precipitation tank. When the concentration of gold in the leaching solution is 15mg/L, CNFREE ECO gold leaching agent is 0.015%, and oxygen is 0~3.1mg/L,the volume of added zinc is 1g/L, and the recovery rate of gold can reach 95%~98%.

TOP